Raul Fernandes, July 7, 2025 | Special lubrication covers the most diverse segments of the industry, seeking to overcome the most critical challenges of friction and wear in equipment. In addition to the extreme conditions of load, temperature, vibration, speed, among others, lubricant manufacturers must also meet specific requirements for non-toxicity levels if they want to supply companies within the food production chain.

This article will present everything you need to know about food-grade lubricants, from the definition, importance, classifications, and regulatory standards to the actions needed to ensure your process and consumer safety.

What is a food-grade lubricant?

A food-grade lubricant, also known as simply FGL, is a special lubricant made from restricted raw materials to ensure compliance with health and food safety standards, and is physiologically inert, tasteless, odorless, and internationally approved. For that, the manufacturing process also follows high quality standards to ensure the highest levels of food safety requirements.

We must not forget that, in addition to meeting the non-toxicity requirements, the food-grade lubricant still has the same tribological responsibilities as an industrial lubricant. That is, even under conditions of extreme loads, high or low temperatures, high levels of vibration, solid, water, and chemicals contamination, the lubricant must control in friction and wear between surfaces in contact and relative motion.

Food-grade lubricants can be greases, oils, pastes, dry films, and even release agents, as long as they are formulated and manufactured according to internationally accepted standards. Therefore, several industries within the food production chain use these lubricants, and not only food producers.

Which industries require a food-grade lubricant?

The applications are very diverse, from bearings (grease), chains (oil), screw assembly (pastes) and surface of conveyor belts (dry film), to bread molds (release agents). As such, many industries require the use of food-grade lubricants in their operation to ensure the non-toxicity of their products. In other words, this type of lubricants is not only used in the food industry, but also in segments such as:

- Beverage industry

- Pharmaceutical industry

- Cosmetics industry

- Animal feed industry

- Paper and metal packaging industries

These market segments need a high level of process safety due to direct or indirect work with food products, whether from people or animals, or even cosmetics.

In this article, we will refer to all these industries briefly as food industries or food plant only, for ease of communication.

Why do food safety regulations matter in lubrication?

When it comes to food processing, safety isn’t just a priority, it’s a legal and ethical obligation. One often-overlooked aspect of this responsibility lies in the lubricants used to keep machinery running efficiently. Lubricants are chemical products and present a potential source of contamination if not properly selected and managed. That’s where food safety regulations come into play.

In a typical food plant, hundreds of moving parts are involved—mixers, conveyors, ovens, pumps, packaging lines, and more. All these machines rely on some form of lubrication. But what happens when a lubricant leaks, drips, or is accidentally over-applied? In non-food applications, that might be just a maintenance issue. In food production, it can become a public health risk.

Even a small amount of non-food-safe lubricant contacting food products can lead to product recalls, regulatory fines, reputational damage, or worse: consumer illness. That’s why regulations governing food-grade lubricants are strict, and compliance is critical.

So, food safety regulations are designed to:

- Prevent chemical contamination from direct or incidental contact

- Ensure traceability of substances used in the production process

- Enforce the use of approved ingredients in lubricant formulations

- Maintain hygiene during equipment operation and cleaning cycles

Agencies like the FDA (U.S. Food and Drug Administration) and standards set by NSF International and ISO ensure that only lubricants with safe, non-toxic ingredients are used in food processing environments.

What is more, incidental lubricant contact on food isn’t uncommon. This is a crucial distinction, because in high-speed or high-heat environments, it’s nearly impossible to guarantee zero contact over the long term. That is why most food-grade lubricants fall under the NSF H1 category, as we are going to see, which allows for incidental food contact—that means the lubricant can come into minor contact with food without causing harm.

By mandating the use of certified food-grade lubricants, regulations acknowledge real-world conditions and help reduce the likelihood of contamination without compromising equipment performance.

What are the standards and regulations required for the food manufacturer?

Both manufacturers of food-grade lubricants and the food industries that consume these lubricants must comply with international standards and national regulations, which may vary depending on the country where they operate.

Starting with the food industries, the processes of these companies must be thoroughly examined in terms of cleanliness, contamination, sanitation and quality. In such manner, companies that are most concerned about the safety of their products structure their processes according to the strictest international standards, such as FSSC 22000 and ISO 22000.

These standards define the requirements of a management system with the aim of guaranteeing the safety of its products, covering not only its process, but also that of the supplier companies that participate in the production chain. The use of tools such as HACCP (Hazard Analysis and Critical Control Points) is quite common and always aims to eliminate contamination hazards from products throughout the process through a preventive control system. For example, in a HACCP analysis, the use of a food-grade lubricant in a rolling bearing in an upper part of the machine, may be a form of risk control or minimization.

“Companies that are most concerned about the safety of their products structure their processes according to the strictest international standards.”

In addition, other techniques such as Good Manufacturing Practices (GMP), Good Hygiene Practices (GHP), Good Storage Practices, and Good Agricultural Practices are commonly used in this type of industry. Due to high levels of demand, it is possible that all lubrication points within a food industry are considered high risk of contamination and therefore the application of a food-grade lubricant is necessary.

In Mexico, the regulation of the food industry is in charge of various institutions, with the Ministry of Health, the Ministry of Agriculture and Rural Development and the Federal Commission for the Protection against Sanitary Risks being the main authorities in the matter. These entities issue regulations and provisions to ensure the quality and safety of food. Among the outstanding regulations are the Official Mexican Standard NOM-251-SSA1-2009, which establishes the principles and practices of hygiene for the handling of food, and NOM-030-ZOO-1995, which regulates the production and control of animal feed. In addition, the use of GMP and Hazard Analysis and Critical Control Points (HACCP) are essential in the food production process. These regulations are critical to guide health inspectors and ensure compliance with quality standards in food products.

In Brazil, the Ministry of Health (MS), the Ministry of Agriculture, Livestock and Food Supply (MAPA) and the National Health Surveillance Agency (ANVISA) have issued ordinances and regulations with the aim of ensuring adherence to the HACCP System and other techniques cited by the food industry. Examples of these include ordinances 1428 (November 1993), 326 (July 1997), 40 (January 1997), 46 (February 1998) and resolution RDC 10 (2003), among others. In addition, normative instruction No. 4, of February 23, 2007, published by MAPA, defines the basic hygiene procedures and good manufacturing practices for food for animal consumption, which includes requirements for the use of food-grade lubricants in the production process. The regulation applies to all establishments that manufacture or divide products intended for animal feed and serves as a basis for federal agricultural inspectors in carrying out inspection and monitoring actions. Furthermore, the Brazilian food industry must be aware of their lubricants supplier, as we will see in the next section, Brazil has some more requirements than other countries in the world for food lubricants, such as ISO 21469 as mandatory for all lubricants.

In the United States, food processing facilities are required to comply with several federal and industry standards to ensure product safety and prevent contamination—including from lubricants. The cornerstone regulation is the Food Safety Modernization Act (FSMA), enforced by the FDA, which mandates that facilities implement a Food Safety Plan based on Hazard Analysis and Risk-Based Preventive Controls (HARPC). This plan must identify potential hazards, including chemical hazards from lubricants, and outline control measures. Additionally, most plants follow GMPs under 21 CFR Part 117, which require proper handling and storage of maintenance materials like lubricants. While not legally required, many companies also adopt third-party food safety certifications such as FSSC 22000, SQF (Safe Quality Food), or BRCGS, especially if they export products or supply major retailers.

What are the standards and regulations required for the manufacturer of food-grade lubricants?

In response to this demand for non-toxic lubricants by the food industry, several standards and regulations have been developed to establish quality levels for the formulation and manufacture of lubricants. As for food producers, some specific requirements vary depending on each country’s regulation, but established international standards guide this market.

The United States Department of Agriculture (USDA) is considered an international authority on consumer safety in the food industry. This agency began with the approval and compliance records of food-grade lubricants, dividing them into USDA H1, USDA H2, and USDA H3 categories (which will be explained later).

To obtain such approval, lubricant manufacturers had to certify that their lubricant formulation was made entirely with permitted substances listed by the U.S. Food and Drug Administration (FDA) in regulation CFR-21:178.3570. Even without the need for laboratory testing for approval, this list of permitted substances ensures that the lubricant does not contain toxic and hazardous ingredients for human and animal consumption.

Beginning in September 1998, the independent nonprofit National Sanitation Foundation (NSF) evolved to replace the USDA in new food-grade lubricant registrations. Lubricants already registered previously, which are part of the White Book, were kept with their valid registrations. Currently, the full White Book – Nonfood Compounds Listing Directory can be found at https://info.nsf.org/USDA/psnclistings.asp.

As NSF becomes the world’s leading organization in relation to the registry of food-grade lubricants, the responsible bodies of each country base this certification to regulate the market. However, depending on the country, in addition to the NSF certificate, other documents may be required to register and sell a food-grade lubricant.

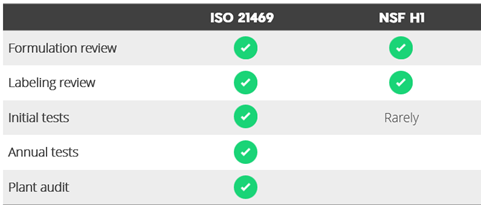

In addition, there is also the ISO 21469:2006 standard for the registration of food-grade lubricants. This standard goes beyond what is required in USDA H1 or NSF H1 certification. The main difference is that in addition to the analysis of the components of the lubricant recipe, the lubricant manufacturing process is also evaluated to see if it is suitable and safe, avoiding any type of contamination from the handling of raw materials to the bottling of the finished product. Other new features introduced include annual audits and laboratory testing of lubricant samples to ensure continued compliance with the requirements of the standard. The full list of lubricants certified as ISO 21469 can also be found at https://info.nsf.org/USDA/psnclistings.asp.

In summary, for the commercialization of food-grade lubricants in Mexico and USA, only NSF H1 registration is required, considering that this classification confirms that the formulations comply with FDA 21 CFR 178.3570. In Brazil, in addition to NSF H1, it is mandatory to comply with ISO 21469 and became the first country in the world with a requirement of this level.

Figure 1: Main differences between ISO 21469 and NSF H1 classification

It is important to remember that, in a family of lubricant oils that has more than one viscosity, it is necessary to certify each of the viscosities separately. Also, in a family of greases with various consistencies, each of the consistencies must be certified separately. In summary, each product must have a specific certification number. Avoid companies with generic certification by product family; this is not allowed.

What are the categories of food-grade lubricants?

As mentioned above, since the USDA is now maintained by the NSF, food-grade lubricant registrations are divided into three categories:

- H1: Certification category for general lubricants that may have incidental contact with food. H1 lubricants are tasteless, odorless, physiologically inert and suitable for accidental and technically unavoidable contact with a food product. For mineral-based lubricants and general synthetics, the maximum permissible concentration of contamination is 10 ppm, i.e. for example 10 grams of lubricant in 1 ton of food. For silicone-based lubricants, the contamination is even lower, at just 1 ppm, or 1 gram of lubricant in 1 ton of food.

- HT-1: Practically with the same specifications as the NSF H1, but it is a category only for thermal oils.

Figure 2: Table with contamination limits

- H2: certification category for general lubricants that cannot have any contact with food. H2 lubricants are for equipment that does not come into direct contact with food and where there is no possibility of the lubricant’s coming into contact with food. In summary, it is to be used outside of the processing area.

- H3: Certification category for soluble anti-corrosion lubricants that must be removed off the surface prior to food processing. H3 lubricants are used to prevent rust on hooks, trolleys, and similar equipment. It cannot have direct contact with food.

A summary is shown in Figure 3.

Figure 3: Summary of main NSF categories

Lubricant companies commonly manufacture other types of products that can also be used by food industries and therefore must comply with the NSF’s list of permitted substances for formulation, depending on the category. We can mention as additional main categories:

- 3H: Certification category for substances for food processing, more specifically release agents. This product can have direct contact with food and has no contamination limit.

- A#: Certification category for cleaning products used in food industry environments. Each type of cleaner is represented by a number ranging from A1 (general cleaners) to A8 (degreasers/carbon removers).

What are the standards that deal with religious requirements?

There are some certifications that may still be required by food industry that consume food-grade lubricants, to ensure that specific requirements, such as religious issues, are met. The two main certifications in this field are known as Kosher and HALAL. Kosher and Halal foods are intended for Jews and Muslims, respectively, so the production of the food is in line with a group of laws called Kashrut (for Jews) and Shari’ah (for Muslims).

“Halal” is an Arabic word that means permissible or lawful, and “Haram” is that which is improper or forbidden. To get an idea of the size of the Halal market, there are more than 1.8 billion Muslims worldwide. In addition, until 2021, Brazil was the largest exporter of Halal foods in the world.

“Kosher” is a word that represents what is allowed, and “Treif” is what is forbidden for Jews. The kosher market is slightly smaller compared to Halal, with only about 14 million Jews in the world. In addition, adherence to Kosher can vary depending on cultural, religious, and geographic factors.

A company that manufactures food-grade lubricants must ensure that the substances used in the formulation of products do not contain elements prohibited by the practices of these religions. Likewise, the manufacturing process must be in accordance with practices, avoiding any contamination with products that are not allowed. This ensures that consumers of these foods will follow all the determinations of their religion. For example, pork and seafood derivatives could be considered as NSF H1, but they are some of the components not allowed in the formulation of lubricants by these certifications.

As a result, it is important to mention that having NSF registration, whatever it is, does not guarantee that the product is Halal or Kosher. These religious certifications are based on international certifications, but they bring more specific requirements to their needs.

In USA, Brazil and Mexico, many companies export food to countries that follow the Jewish and Muslim religions, so Halal and Kosher certifications are very important and required for the supply of lubricants.

Why use a food-grade lubricant?

Technological advancements bring to the market possibilities for improvement in various areas, and therefore, higher levels of requirements. The food industries are not far behind and seek to offer the end consumer an increasingly pure and contamination-free product.

In line with these needs and the regulatory requirements addressed, the first step is always to remove any source of contamination from the products during the manufacturing process. However, it is not always possible to eliminate the risk completely, but only to control it. In most cases, lubricants are classified as a contamination risk, and therefore the need arises to control the risk using food-grade lubricants.

Take the case of a continuous bread oven, with a conveyor belt that carries the breads through the oven to bake them. In this equipment, it is necessary to lubricate the drive chains with a certain oil. Inside the oven, there is a high temperature condition, where there will be evaporation of the oil and possible contact of these vapors with the bread.

This type of exemplified contamination is practically impossible to avoid and, therefore, requires the application of a lubricant that is odorless, tasteless, non-toxic and does not chemically react with the food to modify its properties. That is, it requires the application of a food-grade lubricant—in this case, NSF H1 category (for incidental contact).

Figure 4: Example of a bread oven

In addition to the condition presented, there are other forms of contamination within the food industries, where the application of food-grade lubricants is warranted. These can be mentioned here as the main risks:

- Excessive application of lubricant during lubrication

- Leakage of lubricant during operation of the equipment

- Leaks in tanks and centralized lubricant application systems during equipment operation

- Cross-contamination during cleaning procedures

- Compressed air lines and pneumatic equipment that use lubricants

- Equipment or mechanical elements located near the product

- Disorganization of the lubrication room and the possibility of mixing conventional lubricants with food-grade lubricants

There are often application points that don’t seem to need a food-grade lubricant. For example, air compressors. These machines are usually outside the production area, with no apparent risk of contamination of the compressor oil with food or packaging. However, in screw compressors, the compressed air comes into contact with the oil and transports small particles into the process. If it is the process of blowing plastic bottles, for example, the oil will contaminate the inside of the bottle and, consequently, the beverage that will enter it. A thorough assessment of all implementation points is therefore necessary.

How to choose the lubricant to ensure the quality of your products and operation of machinery

The first step in selecting lubricants in a food industry is to identify the lubrication points of the machines and assess the risk of contact of the lubricant with the food (or with the packaging and objects that may come into contact with the food) at each of the points. In case of technical impossibility to avoid incidental contact, an NSF H1 food-grade lubricant should be used. If contact with the food is constant and necessary, such as in the case of the release agent in a bread pan, or on the conveyor belt of the example before, an NSF 3H category release agent is used.

A general recommendation for a conveyor belt in a bread oven can be seen in Figure 5.

Figure 5: General recommendations for use of each lubricant category

Many companies, amidst so many risks of contamination in their processes and concerned about the quality of their products, use H1 lubricants at all lubrication points, or at least within the production areas. In this way, even in cases of human error in the lubrication activity, such as the use of the wrong product at a risk point of incidental contact, the process will be safe from the point of view of food contamination. Another benefit of using only H1 lubricants in the processing areas is that you will have fewer products to manage, fewer tools to apply it, less inventory and lube room space, and less chance of using H2 lubricants where you should be using H1. Furthermore, you will not be exposed to a possible interpretation by an auditor that is different from yours. Lower parts of the machine may appear to be a clear point for H2, but human error during lubricant application can be considered a source of incidental contamination.

Finally, another important point is to select a high-quality lubricant manufacturer with extremely reliable manufacturing processes, following the rules of lubricant formulation and production and that comply with the standards mentioned before.

Common operating conditions and applications in the food processing plant

Food processing plants operate in some of the most demanding and diverse environments for machinery, and choosing the right lubricant is critical to ensure both performance and safety. Food-grade lubricants are used across a wide range of equipment and applications, each with unique operating conditions that must be considered to avoid equipment failure and prevent contamination risks.

One of the main critical conditions from a lubrication point of view is contamination by water and chemical products, mainly because of CIP (Clean-in-Place). CIP is a cleaning process that removes deposits and contaminants from equipment and piping without disassembly. It uses circulating cleaning solutions, often with increased turbulence, to scrub surfaces and remove residue. This cleaning process often directly attacks lubricated mechanical elements such as bearings, chains and gears. Therefore, grease with high water resistance must be used, as well as oils with excellent anti-corrosion protection. The main grease thickeners that can be used in these conditions are aluminum complex and calcium sulfonate complex. Another strategy is to adjust the relubrication frequency so that it is always done after the CIP.

In high-speed or high-heat environments, it’s nearly impossible to guarantee zero contact over the long term.

High temperatures are also very common in these industries. Bread and cookie ovens, sterilizing ovens, rotating coffee roasters, and labeling machines are some of the applications with mechanical elements subjected to high temperature. Temperatures here can reach 250°C, in some more extreme cases reaching up to 300°C, and the most common components are bearings and chains. In any case, the safest recommendation is to use synthetic lubricants. At these temperature levels, mineral-based lubricants do not offer good performance, carbonize quickly and lose their lubricating properties. In bearings, PAO-based greases with bentone or calcium sulfonate thickeners can be good options. Fluorinated greases (PTFE + PFPE) are the best in terms of thermal resistance, but it is necessary to evaluate the cost-benefit. As with chains, ester-based oils offer the lowest evaporation rate and a clean lubrication, with the lowest residue rate.

At the other extreme, low temperatures are also found in these industries in freezing tunnel applications or areas that must have a low temperature to preserve food. Temperatures can reach minus 40°C, minus 50°C and greatly affect the performance of the lubricants. Mineral lubricants in general cannot withstand these temperatures and can crystallize, completely losing their fluidity. Here too, synthetic-based lubricants are better solutions, especially PAO-based and high viscosity index lubricants. This base can withstand temperatures of -50°C and remains with good flow capacity, ensuring adequate lubrication of bearings, chains and reducers. It is also important to check for proper viscosity. In reducers for example, it may be necessary to use viscosities as low as ISO VG 10, so that at -40°C the oil is in a range of 220 to 320 cSt.

Compressor lubrication is also very common, whether air compressors or refrigeration compressors. Although both are similar, refrigeration compressors may have other, more critical requirements. Firstly, because they can reach very low temperatures, and secondly due to the need for compatibility of the base oil with the refrigerant used in the compressor. Most common fluids used in refrigeration compressors are R-717 (Ammonia), R-744 (Carbon Dioxide / CO₂), R-134a and R-404A. The bases of the most common oils used in these applications are naphthenic minerals (due to low temperatures) and the synthetic polyolesters (POE) as a high-performance option.

MOSH / MOAH Contamination

MOSH (Mineral Oil Saturated Hydrocarbons) and MOAH (Mineral Oil Aromatic Hydrocarbons) are petroleum-derived compounds that can be found in a variety of products, including food-grade lubricants. MOSH refers to saturated hydrocarbons that, while generally less toxic, can accumulate in the body and pose long-term health problems. MOAH, on the other hand, includes aromatic hydrocarbons, many of which are considered toxic and potentially carcinogenic. The presence of these compounds in lubricants used in the food sector has led to a growing interest in regulating and controlling their use.

There is no doubt that MOSH and MOAH are present in mineral oils used as base oils for food-grade lubricants (FGL). However, when mineral oils are refined to FGL, MOAHs that may be considered potentially hazardous (i.e., those consisting of three or more polycyclic aromatic compounds) are removed, leaving at most small traces in the final lubricant. With our current knowledge, exposure to MOSH poses no concerns to human health, but there are uncertainties about its long-term accumulation (AGRINFO 2024, European Union, Mineral Oil Hydrocarbons in Food).

Adding complexity to the discussion about MOSH and MOAH is the difficulty of accurately determining the origin of these substances when they are detected in food. Sources of this contamination can include packaging materials, environmental exhaust gases, lubricants, or food additives. Therefore, it is more difficult to relate studies of the harms of MOSH and MOAH to human health directly to contamination by mineral-based lubricants.

In any case, some food companies, mainly in Europe, are already starting to require MOSH- and MOAH-free lubricants. Therefore, synthetic lubricants should be recommended as a replacement for any mineral-based lubricants.

This topic is much more complex and continues to be studied around the world, so we could dedicate an exclusive article to talk about it.

5 myths related to food-grade lubricants

Myth #1: FGLs are edible.

First, you need to understand which category you are considering. In general, when you talk about food-grade lubricants (FGLs) you are targeting lubricants registered as NSF H1. These lubricants are not edible and should be used with the same care as any other lubricant when handling them. Only minor contaminations in food are accepted, within the limits seen above.

Myth #2: FGLs are underperforming.

When the first food-grade lubricants began to be developed and produced decades ago, there was a huge gap between their performance and that of industrial lubricants. However, today this gap is increasingly close, and many food-grade lubricants can offer similar or even greater performance than industrial products.

Myth #3: FGL options are limited.

It is also a decades-old reality that no longer exists. With the technological development of new oil bases, new additives and synthesis processes, it is now possible to have food-grade lubricants for any application, for example, lubricants for bearings, bushings, chains, gears, reducers, compressors and much more.

Myth #4: If it’s FGL it is automatically allergen-free, Halal, and Kosher.

Having the NSF H1 registration does not guarantee that the product is allergen-free and much less that it is HALAL or Kosher, as it looks. For example, peanuts are a food and could be registered as H1, but they are considered an allergen. Therefore, these mentioned categories are always viewed individually.

Myth #5: Only food producers use FGL.

As seen at the beginning of this article, many industries may require a food-grade lubricant. Producers of animal food, food packaging, cosmetics, and even metal processing companies (which will be used as food packaging) are some examples of potential market for food-grade lubricants.

Enhancing food safety through certified lubrication professionals

In food processing, ensuring product safety isn’t just about clean equipment, food-grade lubricants or compliant ingredients—it’s also about the people responsible for keeping machinery running reliably and contamination-free. One of the most effective ways to strengthen food safety programs is by investing in training and development of the professionals involved. Going a little further, this includes certifying these lubrication professionals who must understand both the technical and regulatory demands of food-grade lubrication.

Improper lubrication is a hidden risk in many food plants. From using the wrong type of lubricant to over-applying grease near open product zones, small mistakes can lead to serious consequences like contamination, product recalls, or non-compliance during audits. Certified professionals are trained to prevent these issues by applying best practices, selecting the right lubricants, and maintaining equipment in a way that supports food safety standards.

The International Council for Machinery Lubrication (ICML) has addressed this need with the Food Processing Lubrication (FPL) badge certification. This globally recognized credential is designed specifically for lubrication technicians and maintenance professionals working in food and beverage environments. It covers key areas such as:

- Food-grade lubricant selection and application

- Regulatory compliance (FDA, FSMA, ISO 21469, etc.)

- Risk-based lubrication practices

- Hygiene and contamination control

- Storage, handling, and labeling procedures

Professionals who earn the ICML FPL certification demonstrate a clear understanding of how proper lubrication supports both equipment reliability and food safety. Having certified personnel isn’t just about passing audits, it reflects a deeper commitment to operational excellence and consumer protection. Certified lubrication professionals help create a workplace culture where every maintenance task aligns with food safety goals, and where lubrication is treated as a critical control point, not an afterthought.

You can find more information about ICML’s FPL certification requirements and body of knowledge on https://www.icmlonline.com/exams/Default.aspx?p=FPL.

Very comprehensive and useful overview of Food Grade Lubricants.. Loved the Myths!

Thank you, Dani

Superb information , great read.

Thank you, Richard, really appreciate your feedback.