So it might come as a surprise for ICML to offer “specialty” certifications within those broad fields. But, thanks to the involvement of technical contributors around the world, that is exactly what the new Lubrication Education Badge Program (LEBP) will do, starting with the “Varnish and Deposit Prevention and Removal” certification badge.

Why a badge program?

ICML’s experience shows that machinery crews staffed with MLA and MLT certificants can save time and money through implementation of best lube and analysis practices. Such newfound efficiency opens opportunities for these practitioners to dedicate their attention toward specific problem areas, thus increasing their value to employers and clients. The ICML board surmised that specialized certification “badges” could help practitioners address such problem areas effectively.

“The program is founded on a series of short duration training sessions that provide focused learning on fewer topics than our larger certification programs,” explains Alec Meinke, Sr., Equipment Reliability Manager at Blue Buffalo Company, who serves on ICML’s board of directors and coordinates the badge program.

Brittle deposits resulting from oxidation and salt water contamination. — Photo courtesy of Jatin Mehta, Fluitec International

“Not only will the badge program improve machinery reliability and life cycle costs through the collaborative application of best practices,” continues Meinke, “but we will also incorporate benefits (ROI, AU, TLCO, etc.) awareness training for industrial stakeholders and financial decision makers.”

Some plants may find it practical to hire or otherwise engage badge specialists rather than lubrication generalists. So, instead of focusing on hierarchical certification levels, the LEBP can provide end users with flexibility to match training and certification to their plants’ specific needs.

A badge will function like a traditional certification. It will involve similar requirements, utilize its own body of knowledge for training purposes, and feature a three-year life span, though a badge exam itself will likely be shorter than a standard exam. Badges will be offered as standalone certifications rather than supplements, regardless of whether a candidate has previously earned any other ICML certifications.

Why varnish?

Due for rollout in late 2019, the badge program’s initial offering will be the “Varnish and Deposit Prevention and Removal” (VDPR) certification badge. With this badge, practitioners can validate their qualifications to perform tasks related to lubricant degradation, lube-derived deposits, contaminant interactions, proactive mitigation technologies, and more.

The ICML board selected varnish as the initial LEBP topic because its prevalence in the field easily merits a standalone training curriculum—and because varnish challenges are on the rise.

If varnish were found only in cases of abuse or neglect, the corrective maintenance solutions would be obvious and ICML probably wouldn’t have considered a certification badge for it.

“Deposits and varnish comprise one of the major problems we have to face, and there is a huge increase in recent years due to more powerful equipment, modern lubricants’ chemistry, and more demanding working conditions,” observes Rüdiger Krethe, MLA-II, Managing Director at OilDoc GmbH. “They are responsible for a serious number of component failures and unscheduled downtimes in many applications. A standalone certificate gives proper attention to this matter and what is needed to overcome it.”

Krethe is one of several volunteer subject matter experts invited by the ICML board to form a committee to develop the new varnish badge. Among others, his fellow committee members include Muhammad Naseer Uddin, MLA-II, Sr. Reliability Engineer at Petroleum Development Oman; Jatin Mehta, MLA-I, Research Engineer at Fluitec International; and Matt Hobbs, MLT-I, Sr. Chemist at EPT.

“Varnish is currently a significant problem in many industries since it impacts a wide range of critical industrial equipment like turbines, compressors, and hydraulic control systems,” says Hobbs. “In our daily work, we all see end users frustrated by varnish problems. So, while we would always recommend as much training as possible with general certifications like MLA or MLT so that end users can become well-rounded lubrication professionals, the standalone nature of the VDPR badge may be useful for those with specific concerns relating to varnish.”

ICML invited technical contributors to develop the “Varnish and Deposit Prevention & Removal” certification badge, the first offering in its Lubrication Education Badge Program. The team includes (L to R) Muhammad, Hobbs, Krethe, and Mehta.

Mehta suggests that ongoing education actually accelerates the need for varnish and deposit specialization. “As more people become aware of proactive maintenance practices, there is a desire to learn more about the difficulties faced due to oil degradation. There is a need to understand the formation and mitigation of varnish and its costly impact on machine reliability, uptime, and profitability,” he says.

The basics of varnish are fairly well documented. Readers of this article certainly know that, even under normal operating conditions, lubricating oil breaks down from extended thermal and mechanical stress, resulting in oxidation that can lead to varnish formation. Varnish is a highly viscous mixture of degradation by-products—solids, liquids, and gases. It generally accretes in machinery by combining readily with any variety of routine contaminants such as carbon-based dirt, metallic particles, water droplets, etc.

Even one of the world’s most modern and efficient gas turbines, a Siemens SGT 800, experiences varnish, despite having separate lube oil and hydraulic oil reservoirs. — Photo courtesy of Muhammad Uddin

If varnish were found only in cases of abuse or neglect, the corrective maintenance solutions would be obvious and ICML probably wouldn’t have considered a certification badge for it. However, varnish is produced naturally even through normal operations, which is why it is an ongoing challenge for all lube maintenance personnel—whether they know it or not—even in the most well maintained machines, and thus its impact has been felt for a long time.

Mehta recalls that the first high profile paper on the growing challenges of varnish in machinery lubrication was written by ICML board member and Noria CEO Jim Fitch in early 1999. And over the years Fluitec’s current CIO, Greg Livingstone, has published multiple papers related to oil degradation and varnish mitigation. Livingstone was also instrumental in developing a test method for measuring varnish potential, which is now an ASTM test method D7843.

Even with such ongoing research and attention, however, technology’s pace makes varnish a moving target in actual practice. Echoing Krethe’s comments, Mehta says that “ever-evolving base-stock technology, additives, and advances in equipment design bring in more unique challenges to the understanding of modes of degradation, prevention and removal.”

As a result, “many end users still do not fully understand what varnish is, how it forms and what solution will be best for their needs,” notes Hobbs.

“There is a desperate need to raise the level of awareness with industrial professionals who are responsible to keep machines running for uninterrupted production,” adds Muhammad. “Developing the VDPR badge is the right step for ICML to take, to raise the level of awareness among professionals for improved business performance globally.”

Mehta agrees. “The varnish badge will provide complete understanding of the challenges faced by machinery lubricant practitioners.”

The expert team of technical contributors

Putting the right team together is always key to the success of these kinds of projects. Hobbs, Krethe, Muhammad, and Mehta all jumped at the opportunity to develop ICML’s inaugural badge. Krethe was first invited by ICML to turn his attention to varnish matters in 2016, and he was joined in 2017 by Hobbs and Muhammad.

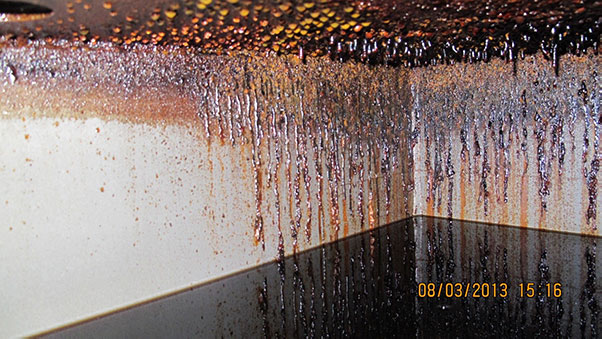

Varnish “stalactites” formed from oil vapor in a lube oil reservoir under vacuum. — Photo courtesy of Jatin Mehta, Fluitec International

But the nature of long-distance communication proved challenging at the outset. Krethe is based in Germany, Hobbs in Canada, and Muhammad in Oman. Finally, when the three men met together face-to-face at the 2018 Reliable Plant Conference in the United States, that’s when things really started to click. “From that time forward our meetings were very productive,” says Hobbs, “and we were joined by Jatin Mehta [in New Jersey] shortly thereafter.”

“Our working team comprises various areas of expertise in the field of lubricant varnish,” explains Muhammad. “Me from the lubricant end-users perspective, to oil analysis expertise labs and oil treatment and varnish removal professionals.”

The foursome collaborated quickly to develop a Body of Knowledge (BoK) library that they believed would best provide VDPR candidates with the knowledge required to effectively solve their varnish problems.

“We had lots of healthy debate and discussion about which topics to include in the BoK,” recalls Mehta. “We all work in the same field, yet we have expertise in regional challenges and some niche applications.”

According to Mehta, the team compiled a BoK that even includes core knowledge that is not readily available in many of the peer-reviewed scientific publications. “The formation of this badge is essential to summarize the industry’s body of knowledge on this topic,” he explains. “We tried to include all the real-world scenarios of oil breakdown, maintenance challenges, mechanical issues, mitigation, and condition monitoring which directly affects the bottom line of a plant.”

The impact of an expert-driven badge program

The VDPR team sees a bright future not just for the varnish badge, but for the overall LEBP initiative.

“It is our hope that the VDPR badge will give end users the tools that they need to effectively solve their varnish problems,” says Hobbs. “A wide variety of varnish solutions are currently available on the market, but we want end users to have the knowledge that they require to make choices that will be effective in their specific circumstances.”

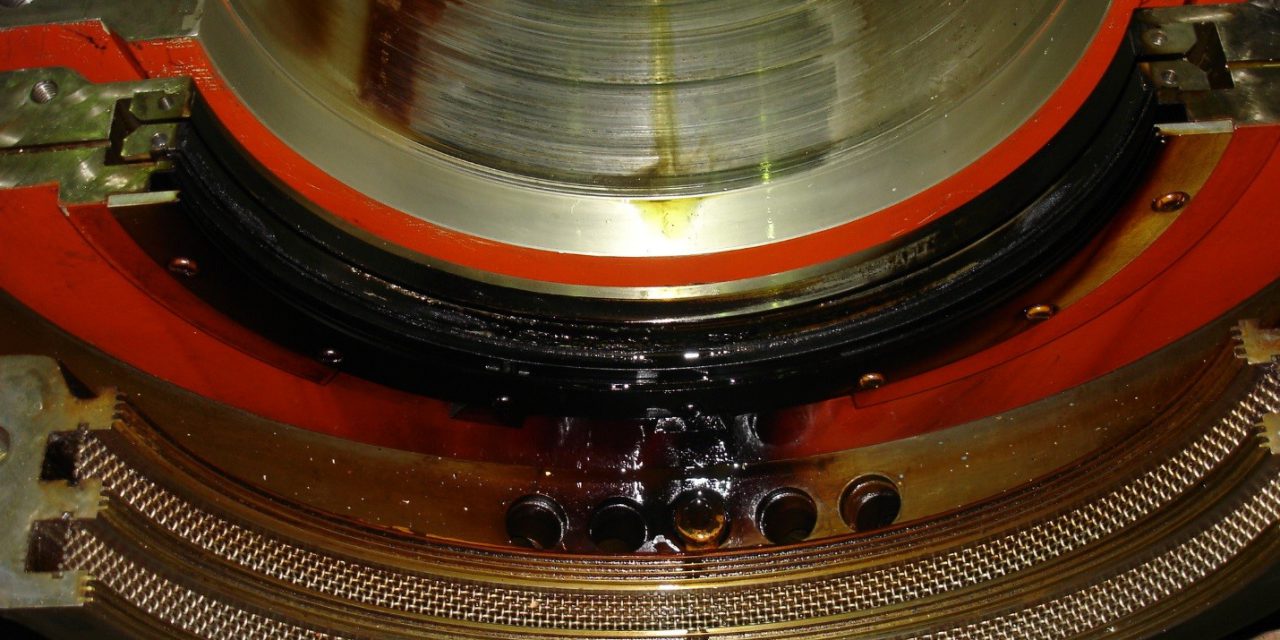

Sticky sludge build-up on a gas turbine filter. — Photo courtesy of Jatin Mehta, Fluitec International

So far, the enthusiasm among the varnish team’s members bodes well for the development of more ICML badges under the LEBP umbrella. “We are all eager to forge ahead with the badge creation to provide end users with the tools that they require to ensure the performance and reliability of their critical assets,” says Hobbs.

Of course, the value of earning VDPR and other badges could be described as incalculable. As Muhammad states, “I hope that the knowledge gained from this badge would readily be implemented by the professionals at their workplaces to improve businesses and save millions of dollars for their companies.”

For his part, Mehta enjoys the opportunity to help the lubrication industry in general. “I feel that sharing your knowledge multiplies your learning, and I am motivated to share my experiences back to the industry,” he says. “And you gain a sense of pride by sharing knowledge and experiences.”

“Agreed,” says Krethe. “Special problems of high importance should be handled in this special way, with an effective working team, helping to overcome the problems people have in their daily work.”

“The most rewarding part of volunteering on ICML’s certification committee is getting to work with my colleagues,” says Hobbs. “Although we are all considered experts in the field of lubrication varnish, each of us brings a unique perspective to the development process. I’ve already learned a great deal from my colleagues, and I hope that my contributions have brought similar new insights to them.”

As of this writing, the VDPR committee is still writing and vetting exam questions. ICML expects to make the new badge available in late 2019, with others to follow.

Subject matter experts interested in learning more about serving as technical contributors to develop future education badges, or to participate with other industry-wide ICML activities, may send inquiries to Marketing Manager Paul Hiller at the ICML office, 918-615-6575 or paulh@lubecouncil.org.